Layer by Layer:

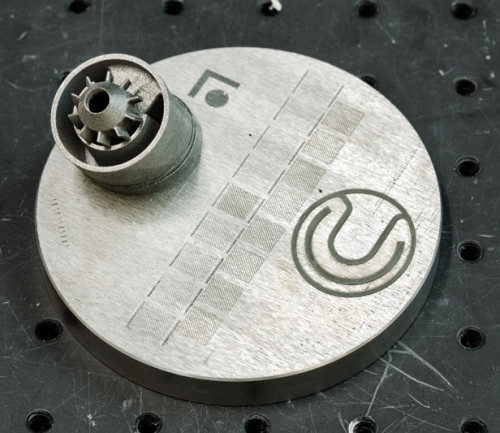

The parts in jet engines have to withstand staggering forces and temperatures, and they have to be as light as possible to save on fuel. That means it's complex and costly to make them: technicians at General Electric weld together as many as 20 separate pieces of metal to achieve a shape that efficiently mixes fuel and air in a fuel injector. But for a new engine coming out next year, GE thinks it has a better way to make fuel injectors: by printing them.Source: Technology Review

With 3-D printing, manufacturers can make existing products more efficiently—and create ones that weren’t possible before.

No comments:

Post a Comment